Computer-controlled Long-Term Cultivation System

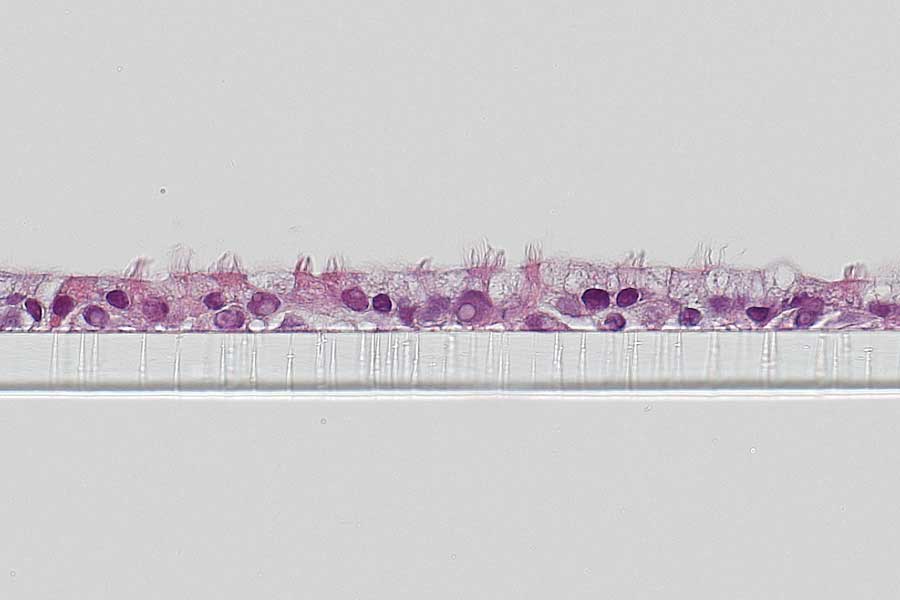

The CULTEX® LTC-C (LongTermCultivation – Continuous) was designed to automatically supply cell cultures with medium at different time intervals over longer periods of time (weeks). In such a way epithelial cells of the respiratory tract, for example, can be used for toxicological studies both in an undifferentiated and differentiated stage of cell development. Medium exchange as well as medium agitation and mixing are computer-controlled to avoid staff-dependent variations during the cultivation process.

For an optimized cultivation process with high reproducibility

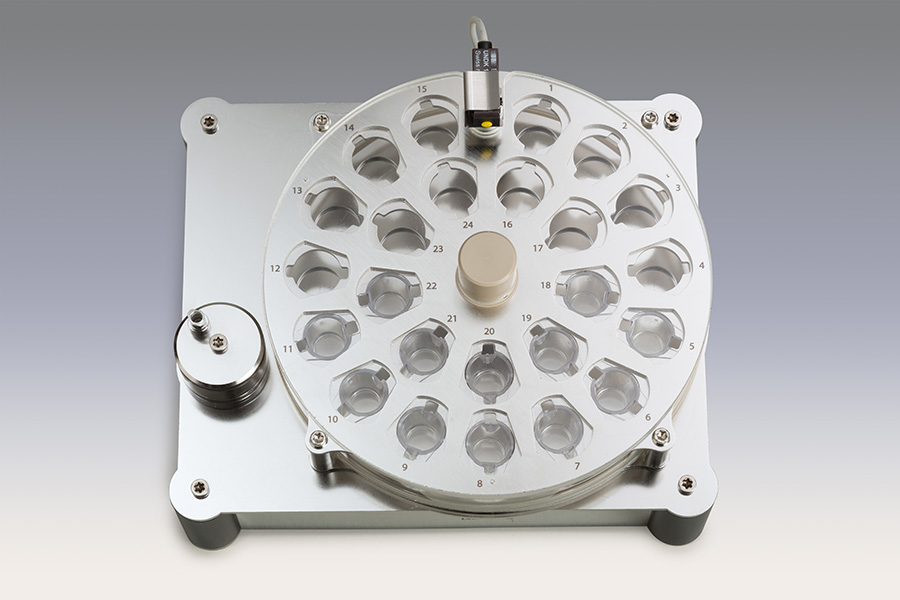

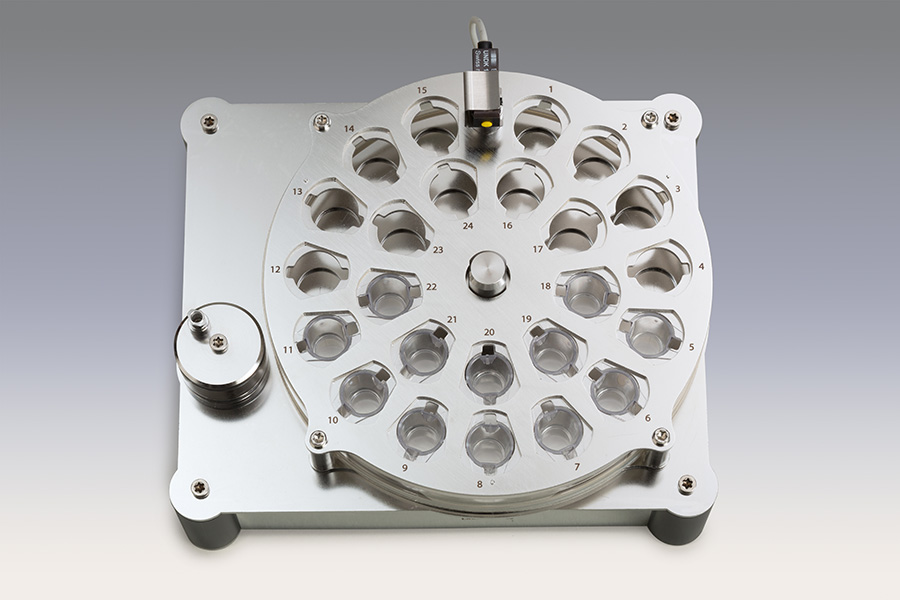

The equipment consists of the incubator module and a supply unit, which can be operated under cell-specific conditions in a CO2 incubator. The incubator module can hold up to 24 cell culture inserts (e.g. COSTAR® or FALCON®, size 12 mm) and is connected to the control unit via two tubes and two electric connector cables.

The control unit is placed outside the CO2 incubator. Integrated in the control unit, there is a programmable logic controller (PLC) as well as a pump for the supply of medium to the incubator module and a pump for the removal of the medium. The pumps are located inside the control unit in a sliding cassette, the LH module (LH = Liquid Handling), where they are easily accessible for maintenance and sterilization.

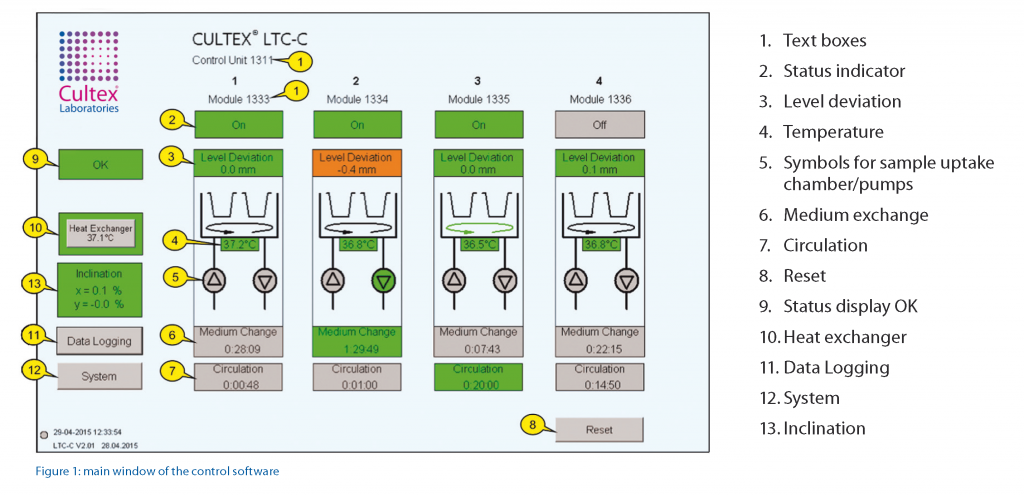

The control unit is equipped with an integrated web server. Visualization of the procedures and measured data is carried out by a web browser, e.g. via a laptop computer. The controls can also be accessed via the web browser, to change settings, for instance. The computer itself does not carry out any control tasks, whereby the management of the cell cultures continues even if the computer operating system breaks down.

The fully automated CULTEX® LTC-C requires less manual work compared with standard cell culture work, saves manpower and removes the individual influence of the worker.

General features

- Automated cultivation technology for cell cultures at the

air-liquid interface (e.g. cells of the respiratory tract) - Cultivation period: up to several weeks

- Simultaneous supply of a maximum of 4 incubator modules

- Computer-controlled intermittent or continuous medium

supply with regard to medium exchange, agitation and

mixing - Save of manpower and avoidance of staff-dependent

influence and variations

Application areas

- Air-lifted cultures

- Cells from the respiratory tract

- Skin cells

- Cell lines

- Human and animal primary cells

- Mono- and/or co-cultures

- Generation of comparable cultures for mechanistic and toxicological studies

Clients

- Universities

- Regulatory bodies

- Military

- Pharmaceutical, chemical and tobacco industry

- Contract research laboratories

Basic principles of the LTC-C cultivation system

Module design

- The incubator module hold up to 24 cell culture inserts (e.g.

Transwell® or Falcon®, size 12 mm) and is connected to the

control unit via two tubes and two electric connector cables. - The incubator module consists of the sample uptake (autoclavable)

and supply module, which can be operated under

cell-specific conditions in a CO2 incubator.- The sample uptake module has a medium in-and outlet. A motorized mixing disc at the base of the supply module ensures a homogenous mixture of existing and fresh medium after a partial medium change.

- The supply module houses

- the geared motor for the mixing disc,

- an air bubble precipitator for the fresh feed medium

- a temperature sensor underneath the cover plate for monitoring the temperature of the medium,

- an ultrasonic sensor for adjusting the medium fill level in the sample uptake module

- The control unit, equipped with an integrated web server, is located outside the incubator. Integrated is a programmable logic controller (PLC), a pump for the supply of medium to the incubator module and one for the removal of the medium. The pumps are incorporated inside the control unit in a sliding cassette, the LH module (LH = Liquid Handling).

- LH module (LH = Liquid Handling):

- The main components of the LH module are the two pumps for medium supply and removal.

- The heat exchanger (preheating of the fresh medium to 37°C). Control by two redundant temperature sensors and an excess pressure valves guarantees trouble-free operation.

- The leakage sensor. All medium-carrying components can be autoclaved.

- Visualization of the procedures and measured data is carried out by the web browser, e.g. via a laptop computer. The controls can also be accessed via the web browser, to change settings, for instance. The computer itself does not carry out any control tasks, whereby the management of the cell cultures continues even if the computer operating system breaks down.

Control Software

- Operation of up to 4 modules with one control unit by using a web browser (JAVA plugin). The main window supplies the most important information on current and/or pending process steps and offers direct access to all secondary windows for further adjustment.

Handling

- Operation of the CULTEX® LTC under cell-specific conditions

inside a CO2 incubator - Control unit outside the CO2 incubator

- Preheating of the fresh medium by a heat exchanger in the

control unit - Air bubble precipitator

- All cell or medium housing components of the system are

autoclavable

Performance

- Requires less manual work and saves manpower

- Computer-controlled continuous or intermittent medium

supply of the cultures - Computer-controlled medium exchange (volume fractions

or the total volume of the incubator module) - Computer-controlled circulation of the medium via a mixing

disc - Control of the medium level by an ultrasonic pulse-echo

sensor

Currently there are no publications available. Please check back soon.